AMR (Autonomous Mobile Robot)

AMR (Autonomous Mobile Robot)

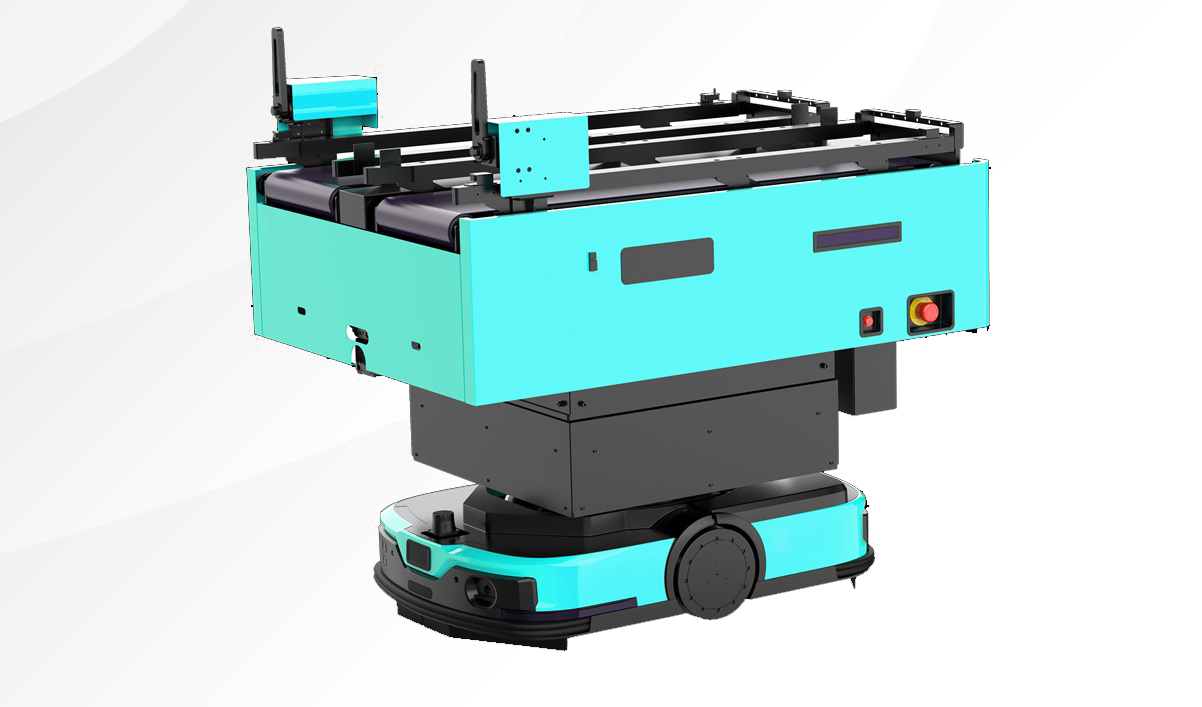

AMR (Autonomous Mobile Robot) is a type of mobile robot that utilizes SLAM navigation and possesses capabilities for environmental perception and intelligent decision-making. It is widely used in the logistics industry. Compared to traditional logistics systems, AMRs can be deployed quickly, with system configuration completed in a relatively short time, and require no shutdowns for facility modifications. AMR systems feature intelligent flexibility, allowing them to dynamically adjust paths and adapt to complex and changing environments. Damon's AMR products can support the coordinated scheduling of over a thousand robots simultaneously. By leveraging efficient scheduling algorithms, overall system efficiency can be increased by 30%. Damon's AMR products are suitable for a full range of scenarios, offer a broad load capacity range, and are widely applicable, meeting the demands of most application scenarios. The current AMR product portfolio at Damon includes:

- Latent Mobile Robot

- Heavy-Duty Mobile Robot

- Conveyor Mobile Robot

- Carton Transfer Mobile Robot

- Forklift Mobile Robot

Features

Comprehensive Product Portfolio

The product line includes latent mobile robots, Carton transfer mobile robots, , forklift mobile robots, conveyor mobile robots, and heavy-duty mobile robots, offering a wide load capacity range. The entire system is built on a unified platform with a modular design, enabling rapid deployment, easy maintenance, and compatibility with a variety of hardware peripherals.Highly Flexible System Design

The system supports multiple navigation modes, such ASLAM and LSLAM, integrated with QR code navigation. Equipped with multi-sensor data perception, it constructs highly accurate maps to support navigation. The robots feature advanced motion control for high-precision positioning and are protected by multi-directional safety measures.Strong Scenario Adaptability

The robots deliver outstanding load capacity with a high load-to-weight ratio. Powered by high-performance batteries, they offer extended endurance. They can be combined with various types and sizes of carriers to meet diverse application needs.Powerful System Scheduling Capability

The product features a well-structured software system with sophisticated scheduling algorithms capable of managing clusters of over a thousand robots, achieving world-leading scheduling performance. The RCS also provides extensive software interfaces for seamless integration with WCS/WMS and other systems.Customization Support

Leveraging strong R&D and manufacturing capabilities, Damon Group can develop custom solutions per client requirements, including customized movement patterns, multi-type robot collaboration modes, and tailored carrier designs. Furthermore, products can be customized for long-term operation in challenging conditions such as low-temperature environments, high-intensity lighting, or flammable substance settings.

-

Standard design

Standard design -

Intelligent control

Intelligent control -

Multiple protection

Multiple protection -

Flexible expansion

Flexible expansion

Model

Q Series

QF Series

Tote-to-Person CU-Series

F Series

Heavy Duty HL Series

Conveyor CU Series

CT Series

How Can We Help?

If you do have any question about our products and solutions, we are happy to communicate with you.

Contact us

Service Support

We provide you with the better advice and quick actions any time after purchasing our products.

Get help

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website.Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link.Read More